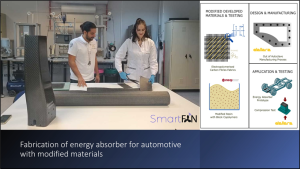

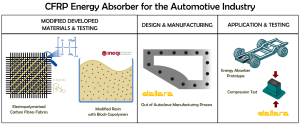

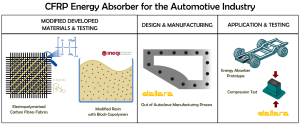

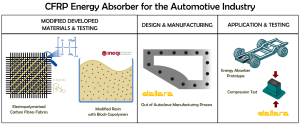

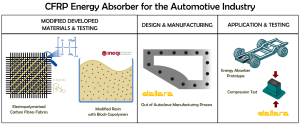

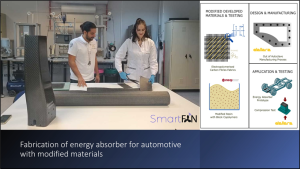

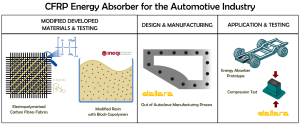

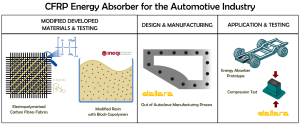

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

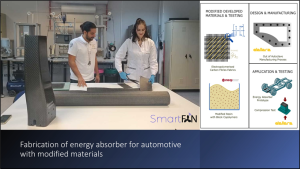

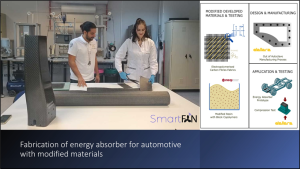

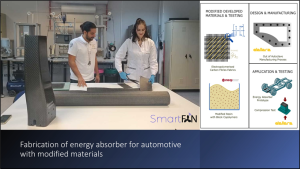

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

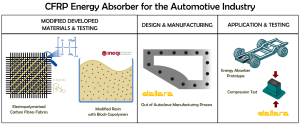

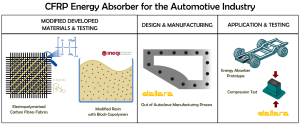

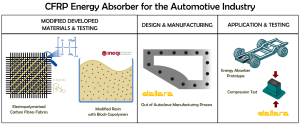

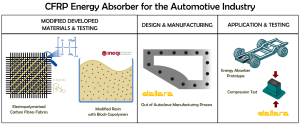

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

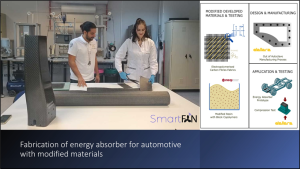

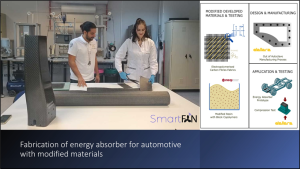

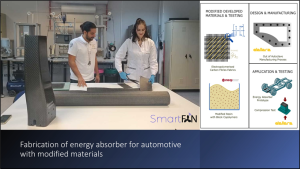

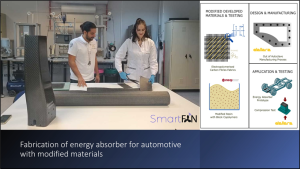

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)

Within the SmartFan EU project, R-Nano Lab collaborated with Dallara and INEGI to design and fabricate an automotive energy absorber, a structural component typically made of aluminium or steel, using carbon fibre reinforced polymers (CFRPs) enhanced through innovative surface modification and impact-toughened resin systems.

To improve the fibre–matrix interface, carbon fabrics were electropolymerized using a conductive polymer coating, significantly increasing interlaminar shear strength and overall mechanical integrity. In parallel, impact modifiers were incorporated into the resin to enhance the absorber’s resistance to crash loads.

The component was manufactured via a compression moulding process, replacing the conventional autoclave route. This method not only reduces the environmental footprint and production time but also demonstrates a scalable path toward high-performance, lightweight composite parts for the automotive industry.

Testing confirmed that the modified materials provided comparable or improved energy absorption while maintaining structural performance under compression loading. The demonstrator successfully validated the use of surface-treated CFRPs in safety-relevant automotive applications.

More details can be found in our publication:

“Design, Manufacturing, and Evaluation of Race and Automotive Prototypal Components Fabricated with Modified Carbon Fibres and Resin,” Polymers (MDPI, 2024)